Smartstage Truss Manufacturing Quality Control

The overall scope of truss (lighting truss, light truss or box truss) test procedure is to make sure with 100% certainty all truss sections will perform under certified load conditions in service.

Procedure to be performed with a combined effort of three companies;

- Smartstage alloy testing team

- Smartstage manufacturing team

- Smartstage engineering team

- The alloy is to be chemically analyzed by batch, for alloy and temper to make sure it conforms to 6061T6. Test reports for each test are to be documented and forwarded to Smartstage via SGS for audit. There are FOUR shapes with the current production run being manufactured at SGS, which means FOUR alloy tests and FOUR temper tests.

- Weld penetration verification on the floor at SGS. SGS is to designate welding “Supervisor”, holding SCWI certification under the AWS designation. This is the most important point of quality assurance. SCWI will visually verify full penetration on the weld by each welder. If this is done correctly, then all testing beyond this will pass.

Welders must be certified under the AWS designation for TIG welding, and pass the test of SGS for the quality of weld before welding the truss. Certification documents must be available for request by Smartstage or a designated authority.

A dye penetrant test will be a secondary verification to weld inspectesting, testing one truss section of every 25. It is a very simple test.

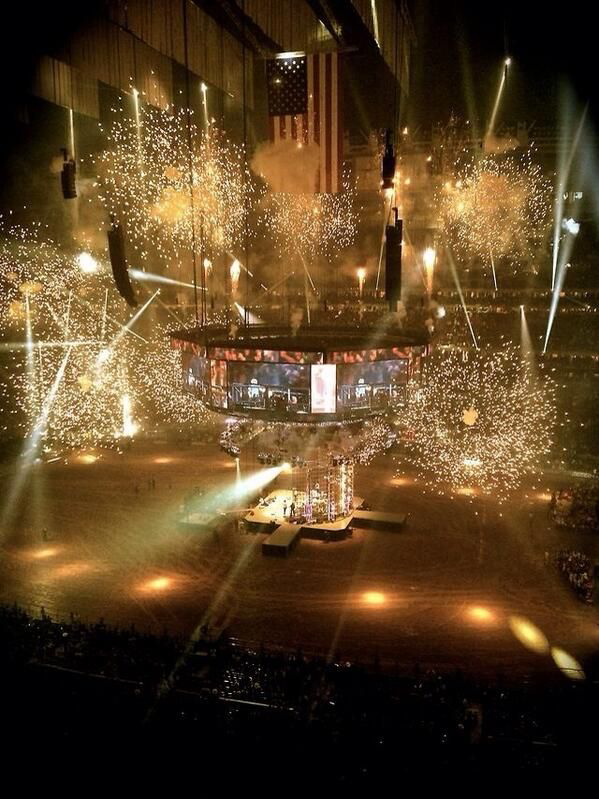

A load test must be performed on every 25th truss. The load test is as earlier performed, see the photo below. Truss bolted to beam with a SUSPENDED load of 423 lbs (193KG) for 5 minutes, gradually applied. This load will vary based on the length of the truss being manufactured. Destructive load test to be performed on one of every 100 trusses, same procedure with a load of 850 lbs (400KG) - All load tests are to be verified by the engineering firm independent of SGS. All data is to be collected by them and forwarded to Smartstage.

- Alloy test report (4)

- Temper test report (4)

- Verification of SCWI & welder certification

- Dye penetrant test results

- NDT results every 25th truss

- DLT results every 100th truss

The Weld operator that actually welds the end plate, must stamp a unique identifying mark on the INSIDE back of the end plate, always in the same spot for audit purposes. The team is to record and track the identifying mark to the welding operator.

Visit Smartstage Why Choose Us and Smartstage Warranty